06 Feb 2022 Limiting propeller to 2500 RPM for noise reduction

Airplanes make noise, that’s a fact. Many people on the ground don’t like noise, that’s another fact. People who don’t like airplanes often point to the noise as the reason they don’t like them. Reducing noise will help us preserve our ability to fly, or at least slow down the decline of aviation and the closure of airports.

In most of Europe, aircraft are subject to “sound tests” to determine how much noise they generate. The procedures to perform these tests are rather complex, and even though I’ve spent some time trying to understand them, I don’t. The bottom line is that you want to generate as little noise as possible while still having excellent climb performance – both to avoid annoying people on the ground, and many airports fix the landing fee based on your official “noise classification” – of course more noise costs you more money.

I have mufflers on my exhaust pipes to reduce that noise, but apparently much (most?) of the noise comes from the propeller. Other similar aircraft that have performed the noise test have found that with the full 2700 RPM that is available to a Lycoming IO-360 with a Hartzell 2-blade aluminum prop, the noise generated will put the aircraft into the highest noise category. Not good.

What have others with the same problem done? 1) Accept the higher cost, and restricted airfields available; 2) change the prop to a 3-blade with shorter blades; 3) slow down the Hartzell prop to 2500 RPM. I’ve chosen option 3 – slow down the prop.

The EAS and OFAC testing process is very rigorous, and understanding that pilots/builders/owners are (usually) human, they will not rely on a promise to always fly at 2500 RPM maximum – they want something physical to restrict the propeller speed. This of course is possible by adjusting the prop governor and is probably the most common way to do this. When I started my test flights, my prop governor didn’t allow the full 2700 RPM and I had to make a few adjustments to allow it to go to 2700 and no more. Not difficult, but time-consuming since it required a test flight, then removal of the cowl, small adjustment, replace the cowl, and another test flight.

Another option that is accepted is a mechanical restriction on the propeller RPM that can be removed in an “emergency” – for example if trying to climb out of a bad situation in the mountains and you feel you need that last 10% of power that you don’t get if you are only at 2500 RPM instead of 2700 RPM. This is what I decided to do, and now I just needed to come up with a method.

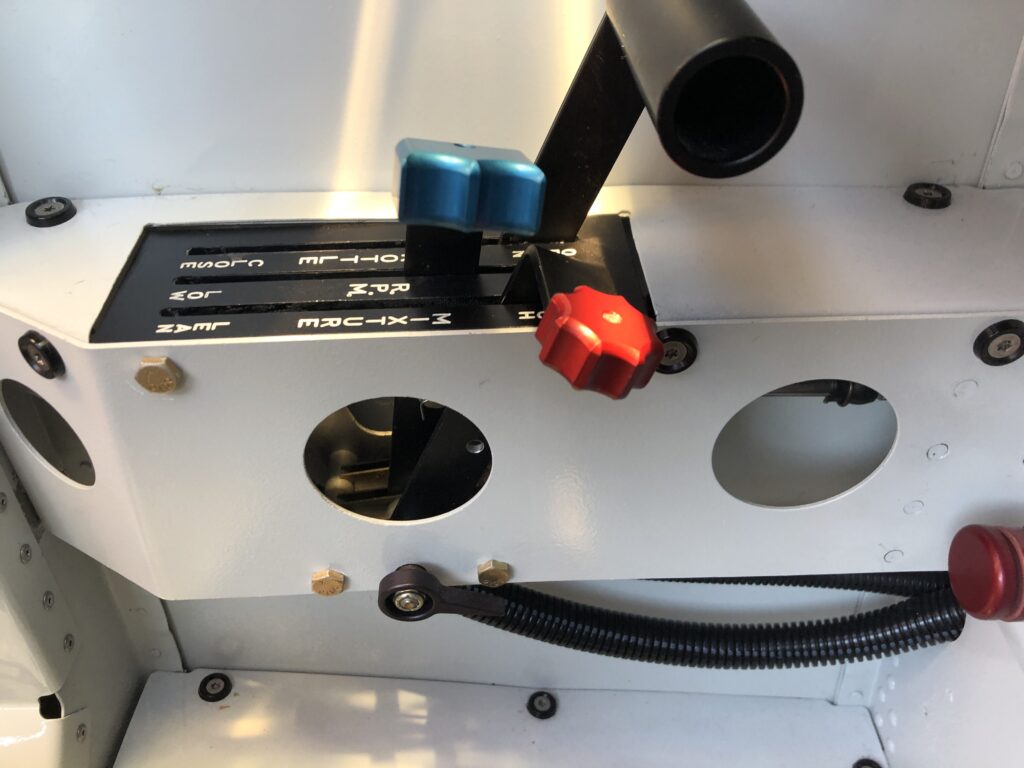

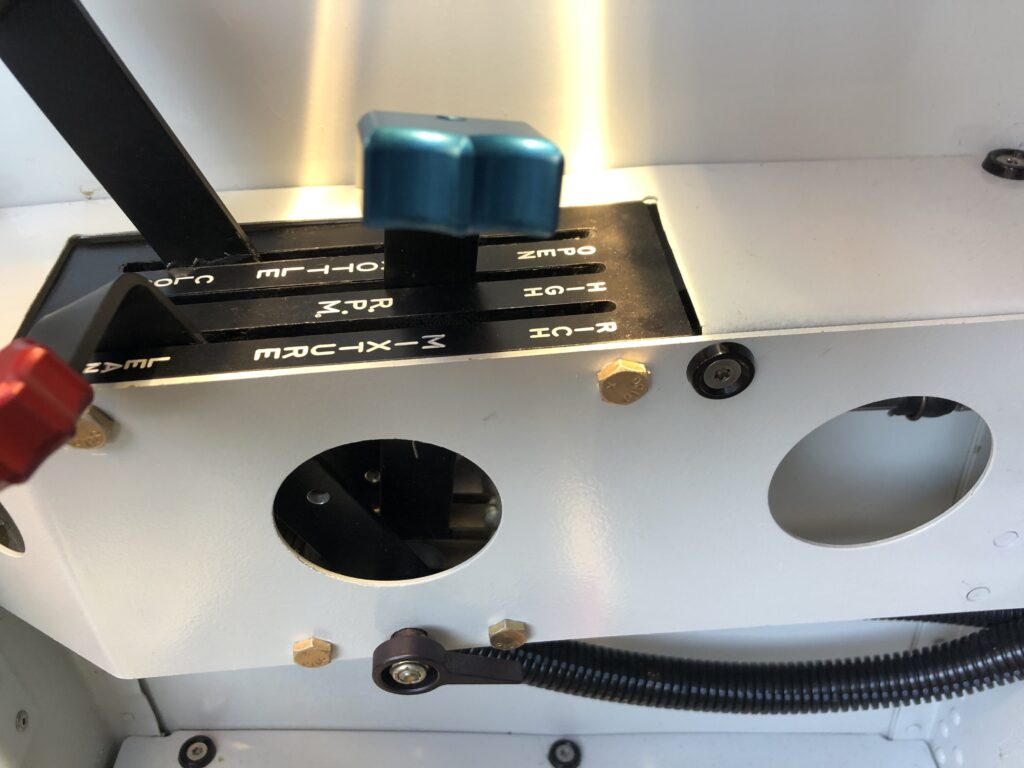

I have levers to adjust my throttle, propeller RPM, and mixture. So at first, I though I would find a way to mechanically limit the prop lever. I thought of several ways to do this and rejected them due to complexity or other limitations. Others that have done this have all apparently had Vernier controls for their prop, and they placed a physical round clip on the cable to limit how far it could go in, limiting the RPM. I thought I had to find a different way, but in the end, my levers also push a control cable, so I can do the same.

I fabricated a small limiting device out of hard plastic tubing, and with several test flights I was able to adjust the exact length to get it to limit the propeller speed to 2500 RPM. Below are some pictures and a short video. The good thing about this solution is that if there is an urgent need to go to 2700 RPM, I can push really hard on the lever and the plastic tube will pop off and allow full RPM. I sincerely doubt I will ever need this, since even without this restriction I never used 2700 RPM for a takeoff or climb, outside of required testing protocols. The performance of my aircraft with 2500 RPM is outstanding.

Sorry, the comment form is closed at this time.