24 Jun 2004 Rear battery mount

Update 20210915: I redid all this to install a much lighter LiFePO4 battery on the firewall. Much simpler, shorter wiring, and the weight is fine. I have a Lycoming with pmags so I’m not electrically dependent. I didn’t install the Eggenfellner Subaru engine, so any post that references that can be ignored or used as a cautionary tale about how to avoid wasting many years and $50k.

Since my engine will be running with electric fuel pumps and an electrically powered computer and electronic fuel injection, I need reliable electricity. Since the Eggenfellner Subaru has only one alternator, this means I need two batteries. I just received the batteries, and I fabricated a mount for them, to be placed in the rear, for CG reasons. The engine I will be installing is about as heavy as a lycoming IO-360, which is pretty heavy.

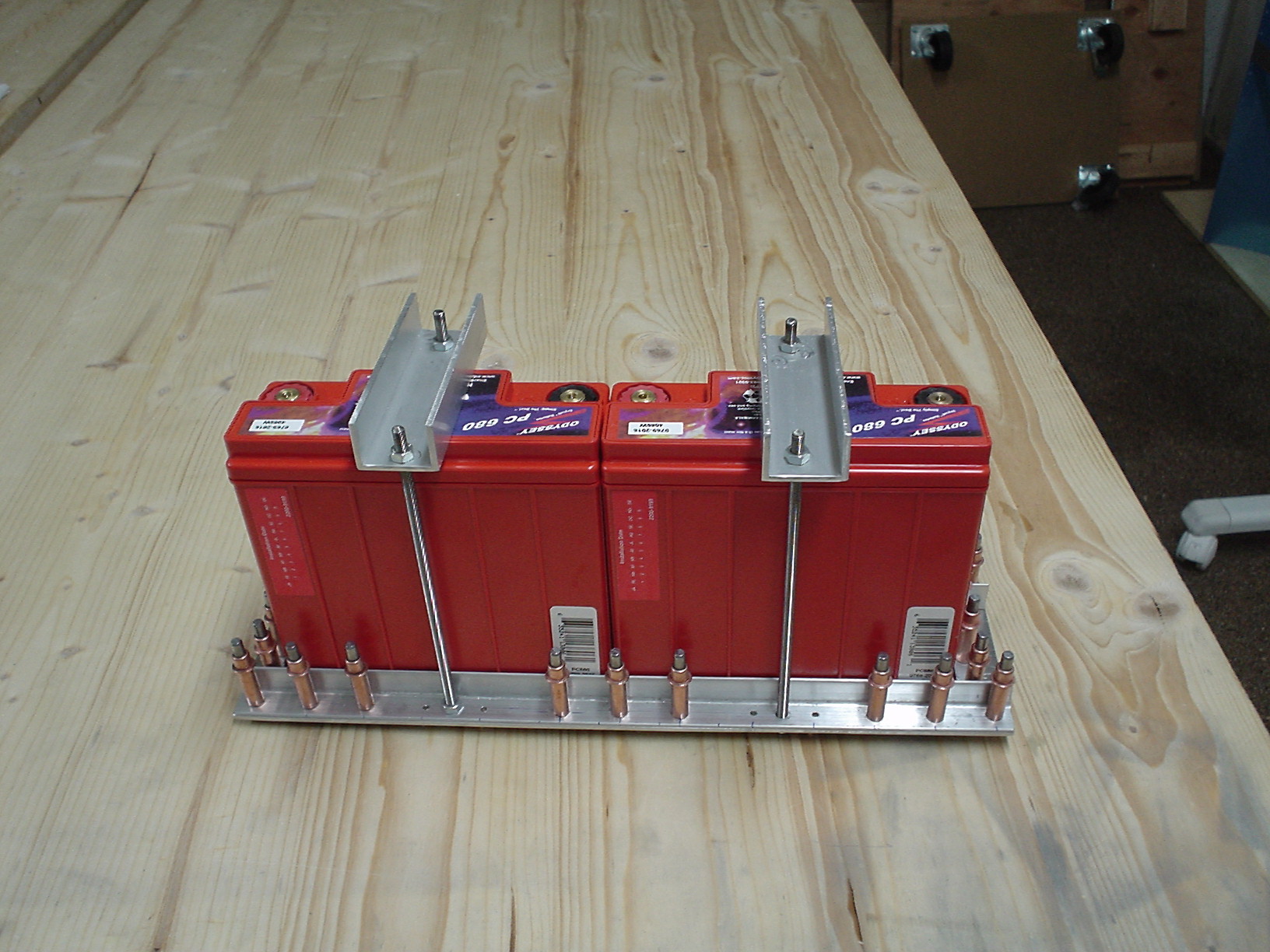

The problem is these little batteries are quite massive, weighing about 15 pounds (7kg) each. I’m using the Van’s recommended location for the batteries, but I’m a bit concerned about the mounting method. They show a whopping 6 8-32 screws to hold on the battery in the rear.

My concern is that in the event of an off-field landing (a euphemism for a crash) these batteries will come flying forward and slap me in the back of the head.

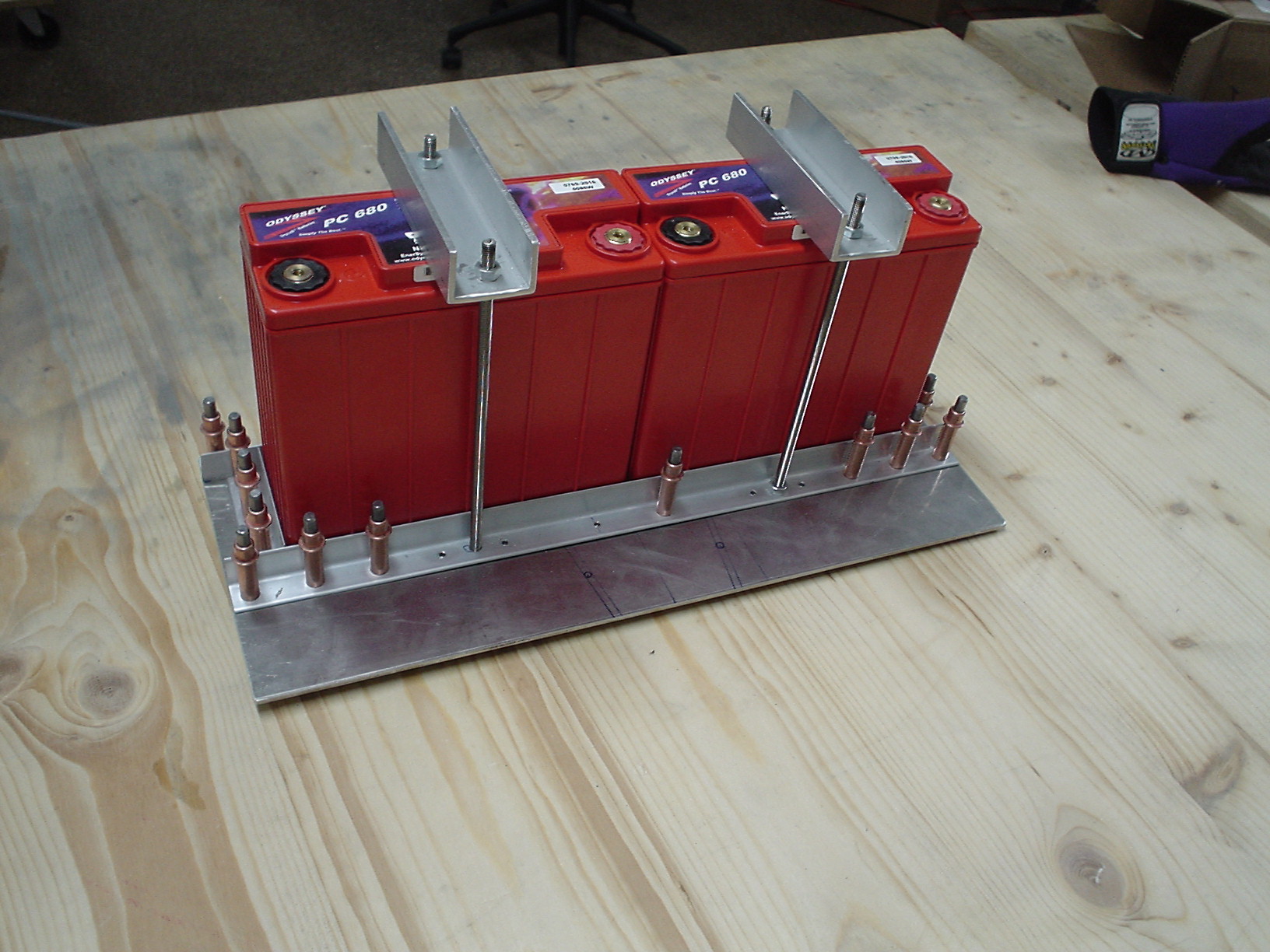

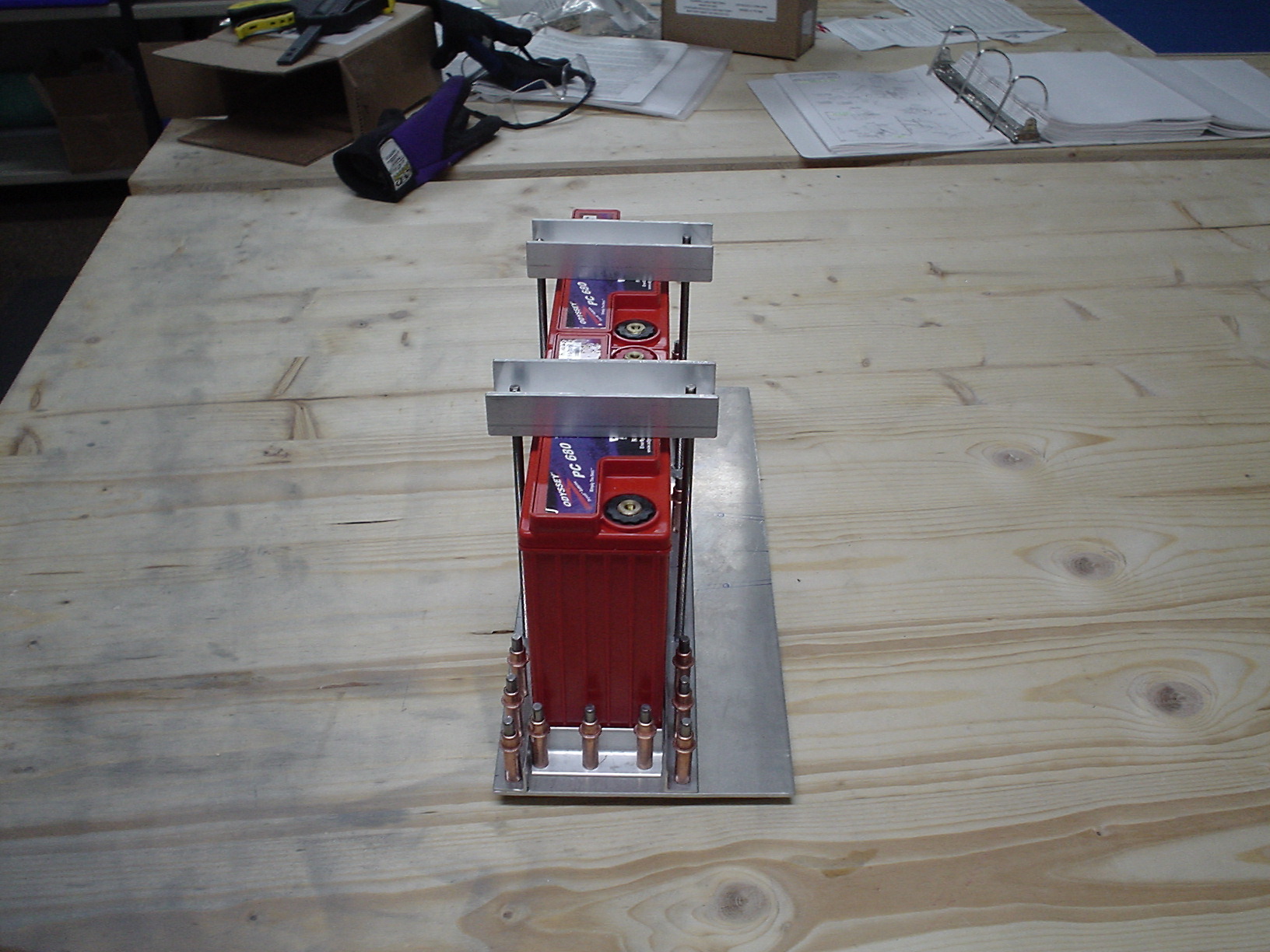

Here are some pictures of the mounting setup I’ve built. It’s pretty sturdy, but I doubt that even 8 screws will handle the 10-20Gs that could be encountered in even a survivable off-field landing.

I’m going to think about this a bit more. I think the batteries would be safer laying down, up against a fuselage bulkhead. Of course, the baggage compartment will be just in front of these batteries, providing some restraining power, but how much? Any suggestions are most welcome!

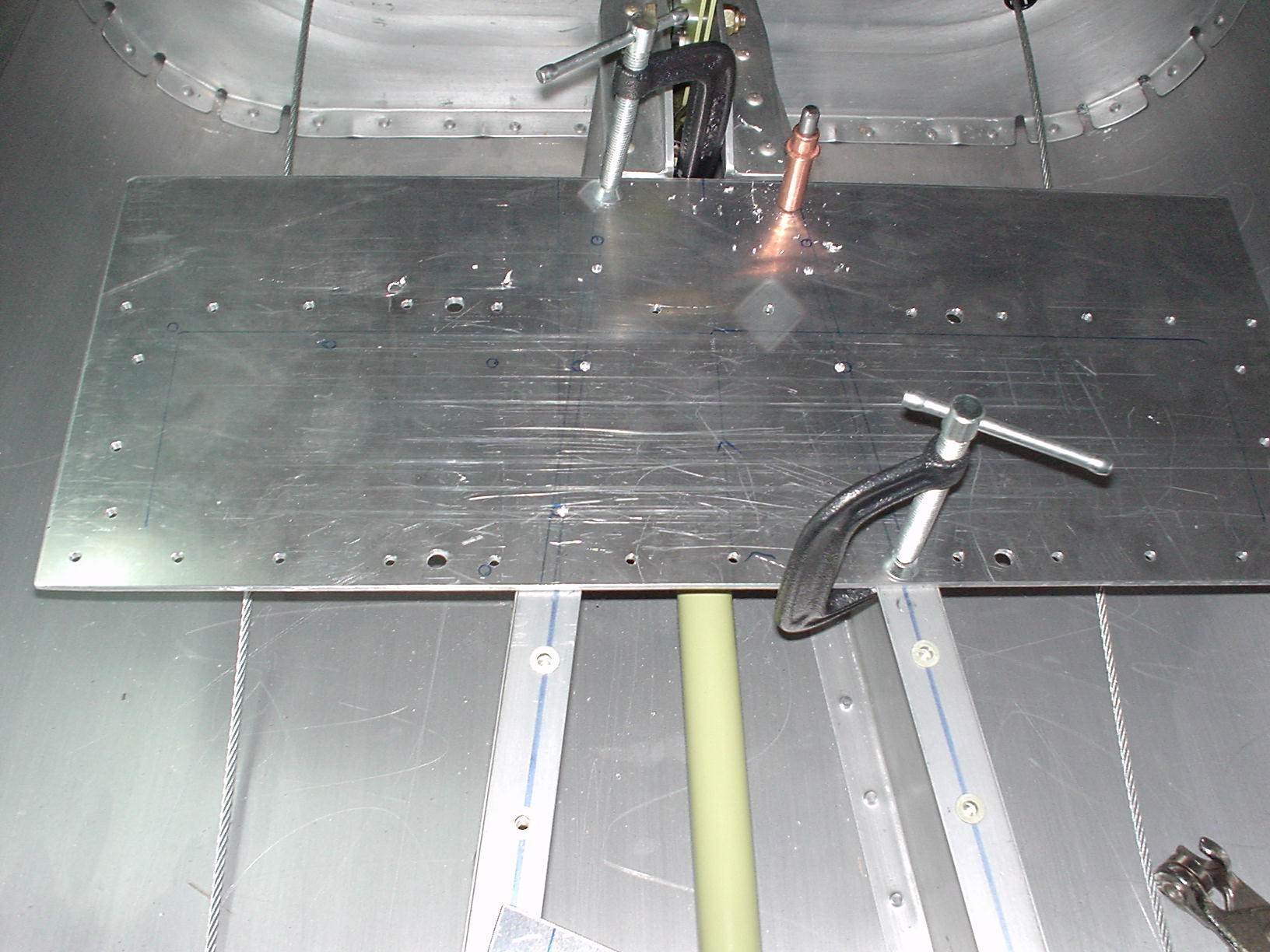

Looking at it again today, I believe that a brace underneath the F-818 baggage ribs will add enough strength to support the battery “box” in case of an off-field landing. Here is a photo of the .125″ 2024 aluminum. I plan to add nutplates into this brace at each one inch line, for a total of 12. I’ll use 8-32 countersunk screws. I’ll probably drill some lightening holes as well.

Update from 23 July 2004:

I decided I don’t need the plate after Emmett ran some stress calculations for me. I’ve decided to install some nutplates, and use 10-32 countersunk screws to mount the plate. The main challenge will be to find a way to keep the batteries attached to this plate if we have an off-field landing. Velcro straps have been suggested to augment the bolts – I kind of like this idea.

Sorry, the comment form is closed at this time.